Product Introduction

The equipment can be flexibly customized according to customer needs to meet the requirements of different production capacities, sites, material

characteristics and packaging specifications. It is an ideal choice for food processing companies to improve production efficiency and ensure product quality.

Core components

1. Bottle unscrambler: Automatically sort and arrange empty bottles to ensure continuous bottle supply and reduce manual intervention.

2. Multi-head weighing and filling machine: High-precision weighing sensor, supports multi-station synchronous filling, small error, fast speed, and adapts

to different granular materials.

3. Capping machine: Compatible with plastic caps, metal caps and other materials, tight sealing, optional torque adjustment function.

4. Labeling machine: Automatic labeling, precise positioning, and support for a variety of label types (such as self-adhesive labels, shrink labels).

5. Bottle collecting machine: Automatic collection and arrangement of finished products for subsequent boxing or warehousing.

Customization advantages

1. Flexible production capacity: Optional semi-automatic or fully automatic mode, support for medium and high configuration upgrades, to meet small batch or

large-scale production needs.

2. Strong adaptability: Customize the receiving tray according to the shape of the bottle, and optimize the equipment structure according to the material

characteristics (such as fragile and easy to damp).

3. Diverse sealing: Match the corresponding sealing machine model according to the material of the cap (plastic, metal, composite cap, etc.).

4. Intelligent control: PLC automation system, easy to operate, low maintenance cost, can be linked to production line monitoring.

Application range

Applicable to quantitative packaging of various nuts (almonds, cashews), beans (soybeans, mung beans), grains and puffed foods, widely used in food processing,

snacks, health foods and other industries.

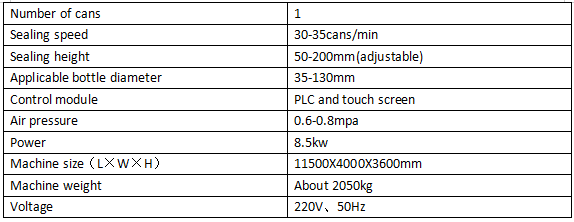

Product Parameters

Tel:+86-15919644519

Mobile:+86-15919644519

E-mail: sales@xinglepm.com

Skype: gmpacky

Whatsapp: +86-15919644519