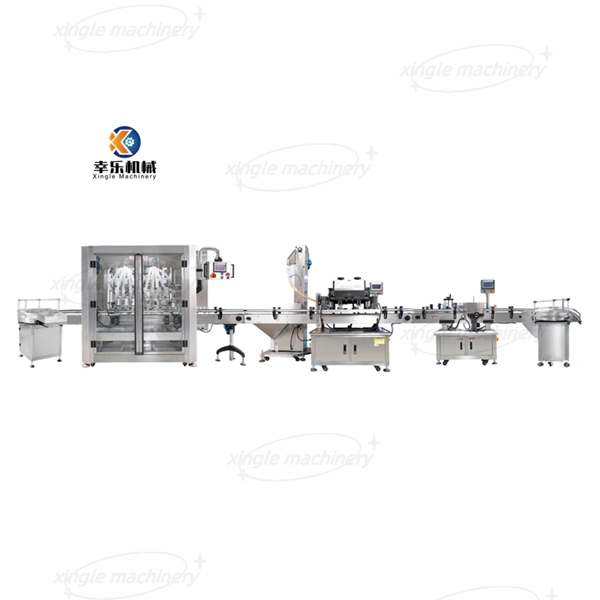

Product Overview

The production line adopts advanced metering technology to ensure high-precision filling, and supports flexible

customization to meet customers' diverse needs in terms of site, production capacity and material properties. It

is an ideal choice for food, daily chemicals, medicine, chemical and other industries.

Core Advantages

Wide applicability: It can fill gas-free liquids and is suitable for low-viscosity to medium-high-viscosity materials

(such as oils, sauces, detergents, cosmetics, etc.).

2. High-precision metering: Using a precision control system, the filling capacity error is ≤±1% to ensure product

consistency.

3. Flexible customization:

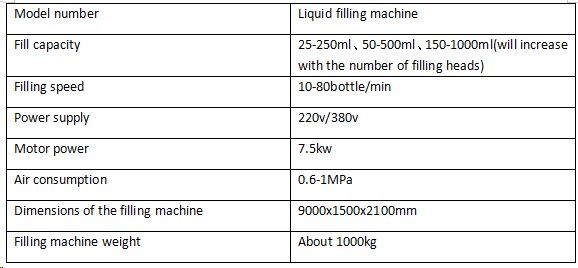

Capacity range: 25-1000ml (multiple gears are optional, and the increase in the number of filling heads can increase

the single capacity).

Adjustable speed: 10-80 bottles/minute, configured according to production capacity requirements.

Design on demand: Customize the equipment material and structure according to material characteristics (corrosiveness,

fluidity, etc.).

Stable and efficient: 7.5kW motor drive, gas consumption 0.6-1MPa, stable operation, energy saving and low consumption.

Application scenarios

Applicable to the automated production of liquid products such as beverages, condiments, lubricants, disinfectants, lotions,

etc., helping enterprises improve efficiency, reduce labor costs, and achieve standardized production.

Parameter

Tel:+86-15919644519

Mobile:+86-15919644519

E-mail: sales@xinglepm.com

Skype: gmpacky

Whatsapp: +86-15919644519